Our Vietnamese factory, JBiChem Vinahealth, is located in Binh Duong, only 25km from Ho Chin Minh port, which is the biggest sea and air port in Vietnam.

The factory is GMP, ISO9001 & ISO22000 certified, as well as EU approved under the Food Section VIII. Besides Glucosamine and Chitosan, we will introduce more products to be produced in this site, because Made in Vietnam has the following benefits:

- The guaranteed sustainable and economical production;

- The supply can help clients to diversify their supply chain and set up competitive differentiation;

- Vietnam is the member of TPP and ASEAN, as well as having the FTA with EU and Korea, hence its products are duty-free to many countries in the world.

Chitin obtained from shrimp shell is the starting material for the production of Glucosamine and Chitosan, therefore we have strongly invested in an optimal local supply:

- Our JV Chitin factory, JBiChem Ca Mau, is situated in Ca Mau in the center of the Mekong Delta, where 70% of the Vietnamese shrimp processors are located;

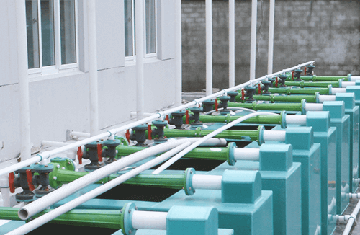

- We built a state-of-the-art Chitin production line in the factory of our strategic partner, a leading Vietnamese shrimp protein producer, to use their wasted shell to produce the Chitin for us exclusively.